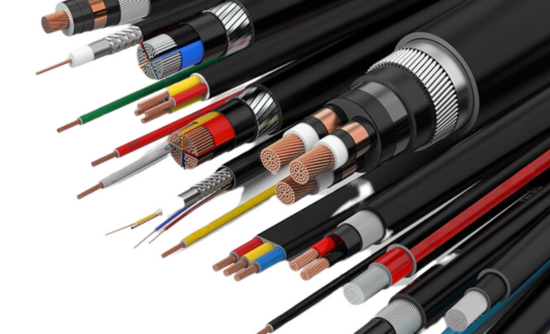

I. Introduction

Power cables form the backbone of any electrical system, channeling electricity from the source to various appliances and equipment across a multitude of environments. Their pivotal role in ensuring the safe and efficient distribution of electrical power makes the selection of the appropriate cable type a critical decision in any electrical installation project. Whether for residential, commercial, or industrial applications, the choice of power cable impacts not only the functionality and reliability of the electrical system but also its safety and longevity.

Selecting the right power cable requires a clear understanding of the specific requirements of the project, including voltage levels, current carrying capacity, and the environmental conditions the cable will be exposed to. Factors such as exposure to moisture, chemicals, extreme temperatures, and physical stress dictate the need for specialised cables, such as armoured or heat-resistant varieties. This foundational knowledge ensures that each electrical system is equipped with the most suitable cable type, tailored to its unique demands, thereby optimising performance and safety.

II. Understanding Power Cables

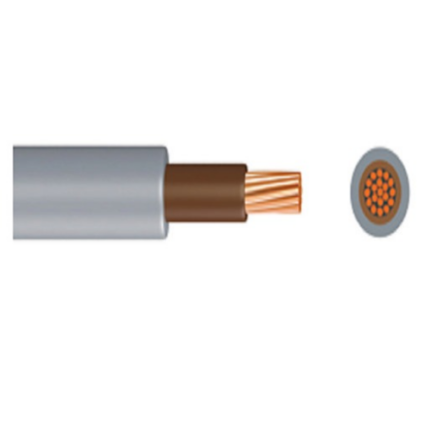

Single-core cables, characterised by their straightforward design and efficacy, play a pivotal role in electrical systems where individual wires are necessitated for each circuit. These cables comprise a single conductor, typically made of copper or aluminium, encased in insulating material. The insulation prevents electrical leakage and ensures the system's safety, while the singular conductor facilitates efficient electric power transmission.

The primary advantage of single-core cables lies in their uncomplicated design, which allows for ease of installation and maintenance. They are particularly favoured in high voltage applications and environments where space is not a constraint. The single conductor's ability to carry higher currents makes these cables an ideal choice for power transmission lines, substation feeders, and other applications requiring electricity transport over long distances. Additionally, single-core cables exhibit less reactance and lower losses, enhancing the electrical system's overall efficiency.

However, their application is best suited to settings where the cables can be laid out straight, as the single, solid conductor is not as flexible as multi-core alternatives. This makes them less suitable for applications requiring cables to bend around corners or in tight spaces. Understanding when and where to use single-core cables is essential in optimising the performance and reliability of electrical installations, ensuring that each project harnesses the best of what these cables have to offer in terms of simplicity, efficiency, and safety.

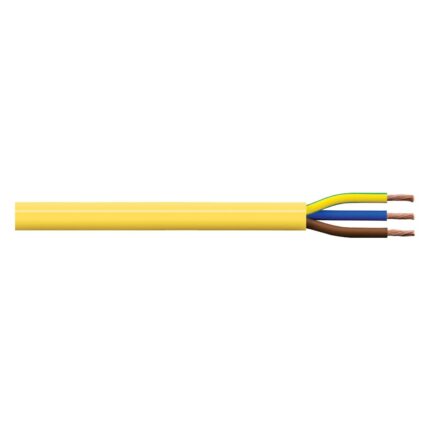

Multi-core cables stand as a versatile and extensively utilised option in electrical installations, characterised by their design that bundles several conductors within a single cable sheath. Each conductor is insulated individually, enabling the cable to carry different circuits or phases concurrently. This makes multi-core cables an efficient solution for scenarios where space is at a premium and multiple signals or power feeds need to be transmitted side by side.

The adaptability of multi-core cables to a variety of environments is enhanced by their inherent flexibility, afforded by the multiple strands composing each core. This feature renders them particularly suitable for applications requiring cables to navigate bends and tight spaces, such as in residential wiring, automotive systems, and portable equipment. Moreover, the consolidated design significantly reduces the physical footprint of the wiring, streamlining the installation process and diminishing the overall complexity of the electrical system.

A key advantage of utilising multi-core cables lies in their capability to support intricate wiring systems whilst maintaining organisation and minimising the risk of installation errors. They are especially beneficial in control systems, audio-visual equipment, and data transmission applications, where managing multiple signals or power sources efficiently is paramount. However, selecting the appropriate type and size of multi-core cable based on the specific requirements of the application, including the voltage rating, current capacity, and environmental conditions, is crucial to ensure the optimal performance and safety of the electrical system.

Twin & Earth cables, integral to UK domestic wiring, feature two insulated conductors alongside an uninsulated earth wire, facilitating safe power distribution in fixed installations. Their design, which combines durability with flexibility, is optimised for use in a variety of residential settings, including lighting circuits and socket outlets. The presence of an earth wire within the same sheathing streamlines the installation process and bolsters safety by providing a straightforward path for grounding in the event of a fault.

These cables are distinguished by their colour-coded insulation, which simplifies identification and ensures compliance with wiring regulations. Available in multiple cross-sectional sizes, Twin & Earth cables allow for precise selection based on the circuit's load requirements, enhancing both the system's efficiency and safety.

The practicality and reliability of Twin & Earth cables make them a cornerstone of electrical installations within the home. Their widespread use underscores the balance they offer between ease of installation, safety, and compliance, making them a go-to choice for electricians and homeowners alike.

Armoured cables are robust, designed to ensure maximum protection in outdoor and underground installations. Their metal armouring safeguards the internal conductors against mechanical damage and environmental factors like moisture, making them perfect for connecting outdoor lighting, powering outbuildings, or any scenario where cables might face physical threats.

Despite their sturdy construction, armoured cables are versatile, suitable for a wide array of environments without needing additional protection like conduit or piping. This makes them highly valued in both residential and industrial settings for their durability and ease of installation. Their steel or aluminium armour not only acts as a shield but also as a grounding mechanism, further enhancing their safety features.

Choosing armoured cables for electrical projects brings peace of mind, knowing that the installation is protected against external damages and is built to last. Their ability to withstand harsh conditions and ensure continuous power supply makes armoured cables a reliable choice for securing the electrical infrastructure of any project, big or small.

Arctic cables are specifically designed to withstand the rigours of extreme cold, maintaining flexibility and performance in conditions where standard cables would fail. Their construction includes special PVC or rubber compounds that stay pliable even at temperatures as low as -40°C, making them ideal for outdoor applications in harsh winter environments, such as construction sites and outdoor events.

These cables are not just about enduring the cold; they're also resistant to oils, greases, and a variety of chemicals, adding to their versatility. The adaptability of arctic cables extends to a broad range of uses, from powering portable heaters in outdoor settings to ensuring the functionality of critical equipment in cold storage areas.

Incorporating arctic cables into installations destined for cold environments ensures that electrical systems remain operational regardless of the freezing temperatures. Their specialised design provides a reliable solution for maintaining power and performance in extreme weather, making them an essential component for any project facing the challenges of cold climates.

Conduit cables are designed for use within protective conduit systems, offering an additional layer of protection in environments where cables may be exposed to potential damage. This setup is particularly beneficial in industrial settings, commercial buildings, and areas where mechanical impact, moisture, or chemical exposure is a concern. The use of conduits safeguards the cables against external threats, extending their lifespan and maintaining the integrity of the electrical system.

These cables come in various types, including single-core, multi-core, and armoured versions, allowing for flexibility in application based on the specific requirements of the installation. Their compatibility with conduit systems means that maintenance and future upgrades can be performed with minimal disruption, as cables can be drawn through or replaced within the conduit with relative ease.

Opting for conduit cables in appropriate settings not only enhances safety and protection but also contributes to a neater, more organised installation. Whether for power distribution, control signals, or communication lines, incorporating conduit cables into an electrical project ensures a robust and reliable setup, poised to meet the demands of challenging environments.

Flexible cables are essential in applications requiring mobility and adaptability, such as in machinery, portable equipment, and areas where cables need to bend or twist during operation. These cables are constructed with multiple fine strands of wire, allowing them to flex without breaking, making them particularly suited to dynamic environments where rigid cables would not suffice.

The versatility of flexible cables extends beyond their physical properties. They are available in various configurations, including single-core and multi-core options, with insulation and sheathing materials designed to withstand wear and tear, as well as environmental factors like oils and greases. This makes flexible cables ideal for use in manufacturing settings, workshops, and for connecting appliances that may be moved or repositioned frequently.

Choosing the right flexible cable involves considering the electrical load, the degree of flexibility required, and the specific conditions of the environment. By selecting a cable tailored to the demands of the application, users can ensure the safety, efficiency, and longevity of their electrical installations, keeping machinery and equipment running smoothly without interruption.

Heat resistant cables are specifically engineered to endure high temperatures without deteriorating, making them indispensable in environments where heat is a constant presence. These cables are constructed from materials capable of withstanding elevated temperatures, such as silicone, glass fibre, or mica, ensuring that insulation remains intact and performance is unimpeded, even when exposed to extreme heat.

The utility of heat resistant cables spans a wide range of applications, from industrial manufacturing processes that generate significant heat to electrical installations near boilers or in commercial kitchens. Their ability to maintain integrity at temperatures that would compromise standard cables not only ensures the safety and reliability of the electrical system but also significantly reduces the risk of fire and other heat-related damages.

Selecting heat resistant cables for applications prone to high temperature exposure is crucial for compliance with safety standards and regulations. Whether for power, control, or signal transmission, these cables provide a robust solution that guarantees continuous operation and longevity of the electrical infrastructure in challenging thermal environments. By incorporating heat resistant cables into the design of an electrical system, engineers and electricians can safeguard against the adverse effects of heat, ensuring that both performance and safety are upheld in high-temperature environments.

Specialised cables are designed to meet the unique demands of specific applications that go beyond the capabilities of standard electrical cables. These cables encompass a broad range of types, each tailored to address particular challenges, including underwater use, fire resistance, extreme environmental conditions, and high-security requirements. The diversity within specialised cables allows for targeted solutions that ensure the safety, efficiency, and reliability of complex and critical systems.

For instance, underwater cables, used for applications such as subsea lighting or equipment, are designed to resist water pressure and corrosion, maintaining integrity and functionality in aquatic environments. Similarly, fire-resistant cables are capable of continuing to operate during a fire, providing essential power to emergency lighting, fire alarm systems, and evacuation signage, crucial for safety during emergencies.

The selection of specialised cables requires careful consideration of the application’s specific requirements, including environmental exposures, mechanical stresses, and regulatory standards. Consulting with experts and manufacturers is vital to identify the most appropriate cable type that meets the technical specifications and safety regulations of the project. By incorporating specialised cables into electrical installations, professionals can achieve bespoke solutions that address the nuanced needs of advanced and high-stakes applications, ensuring optimal performance and compliance with the highest standards of safety and quality.

III. Conclusion

Navigating the diverse world of power cables is essential for the success of any electrical project, underlining the importance of making informed choices to ensure systems are safe, efficient, and perfectly matched to their operational demands. From the robust protection offered by armoured cables in outdoor settings to the specialised performance of heat-resistant cables in high-temperature environments, each cable type brings its unique advantages to the table. This variety ensures that, regardless of the specific requirements or challenges of an installation, there is always a cable solution that can meet the need with precision.

In wrapping up our exploration of power cables, it's clear that the right selection is more than a technical necessity—it's a strategic decision that impacts the functionality, safety, and longevity of electrical systems. Whether it’s for residential, commercial, or industrial applications, understanding the characteristics and applications of each cable type is crucial. As technology evolves, so too does the range of cable solutions available, making ongoing education and consultation with experts a vital part of staying ahead in the field of electrical engineering.